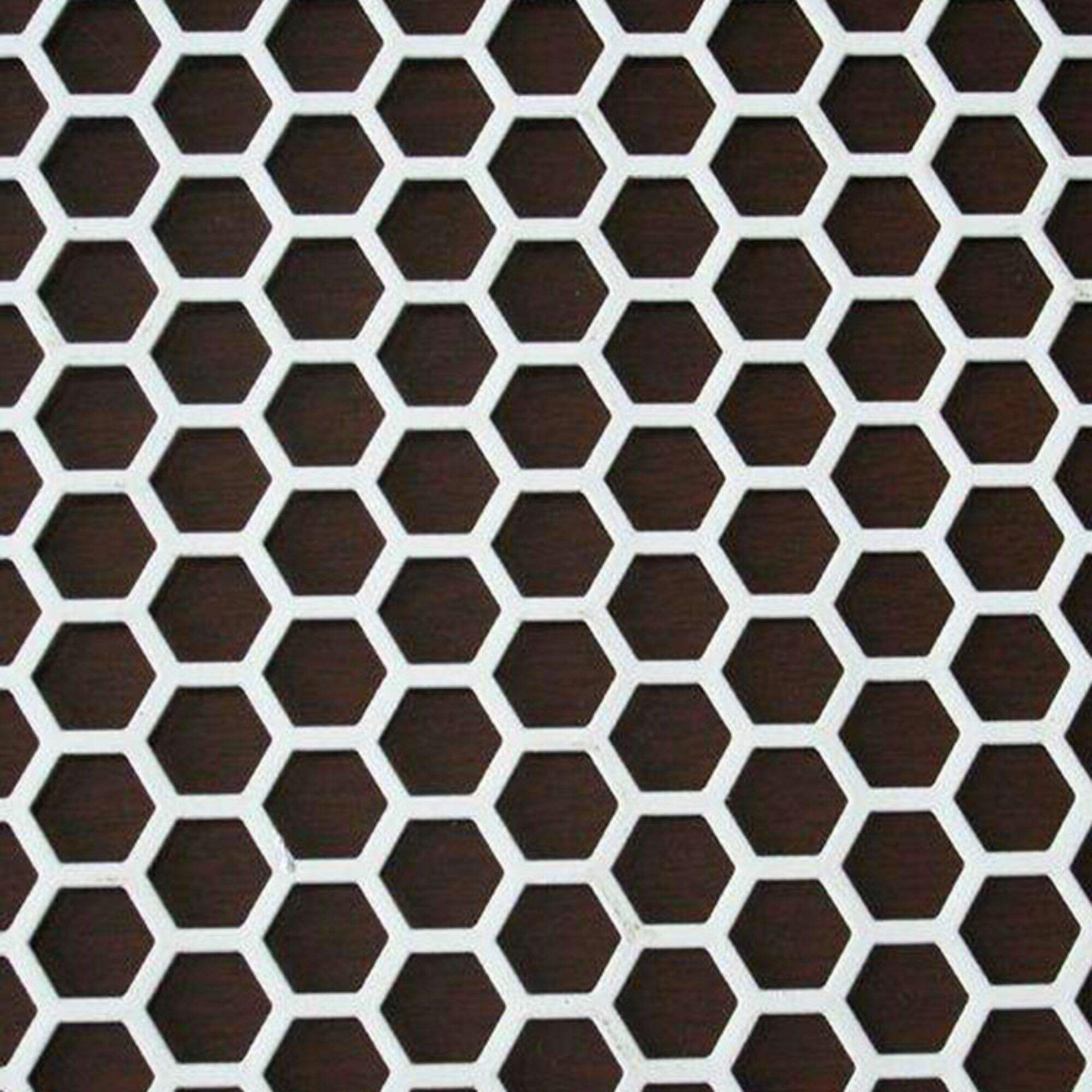

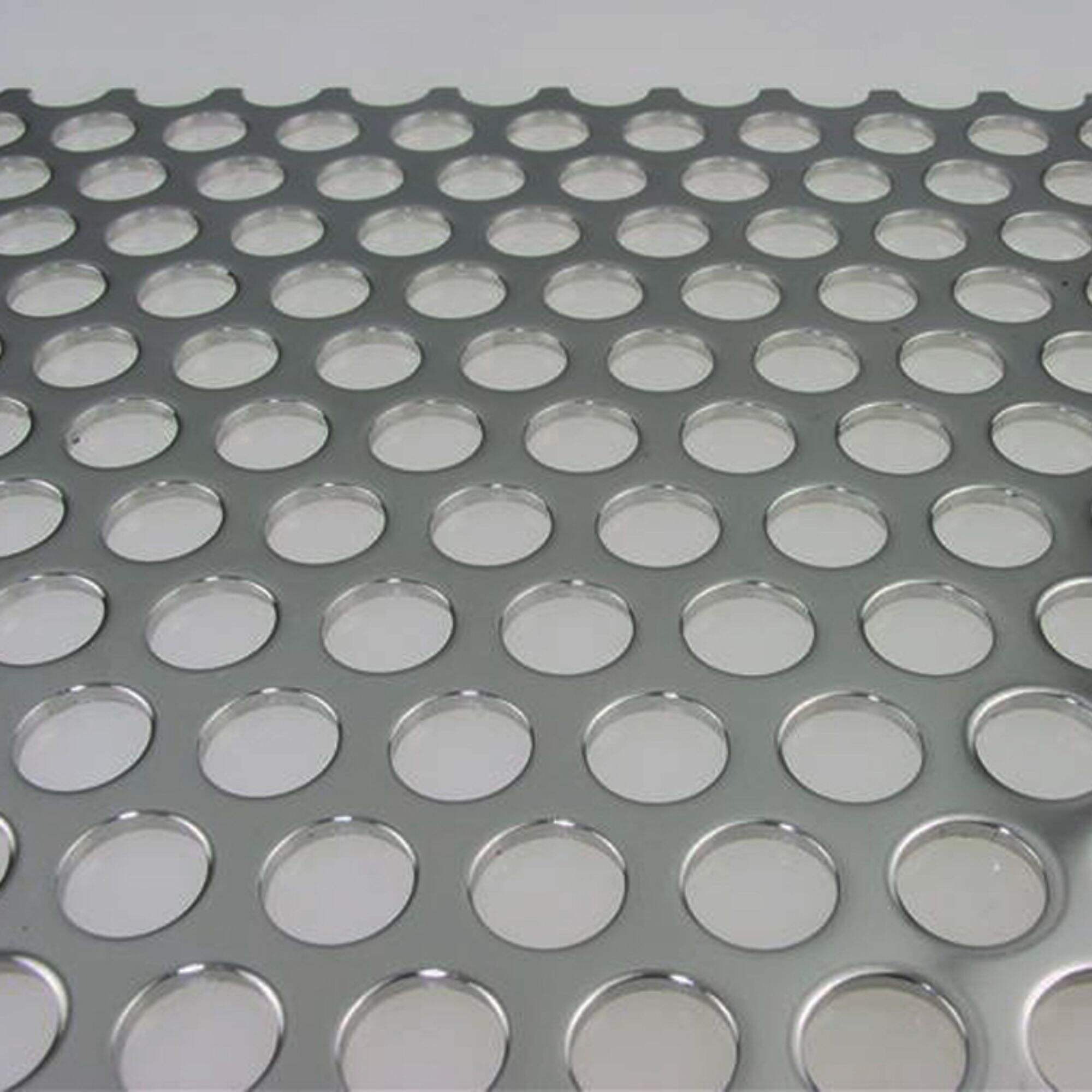

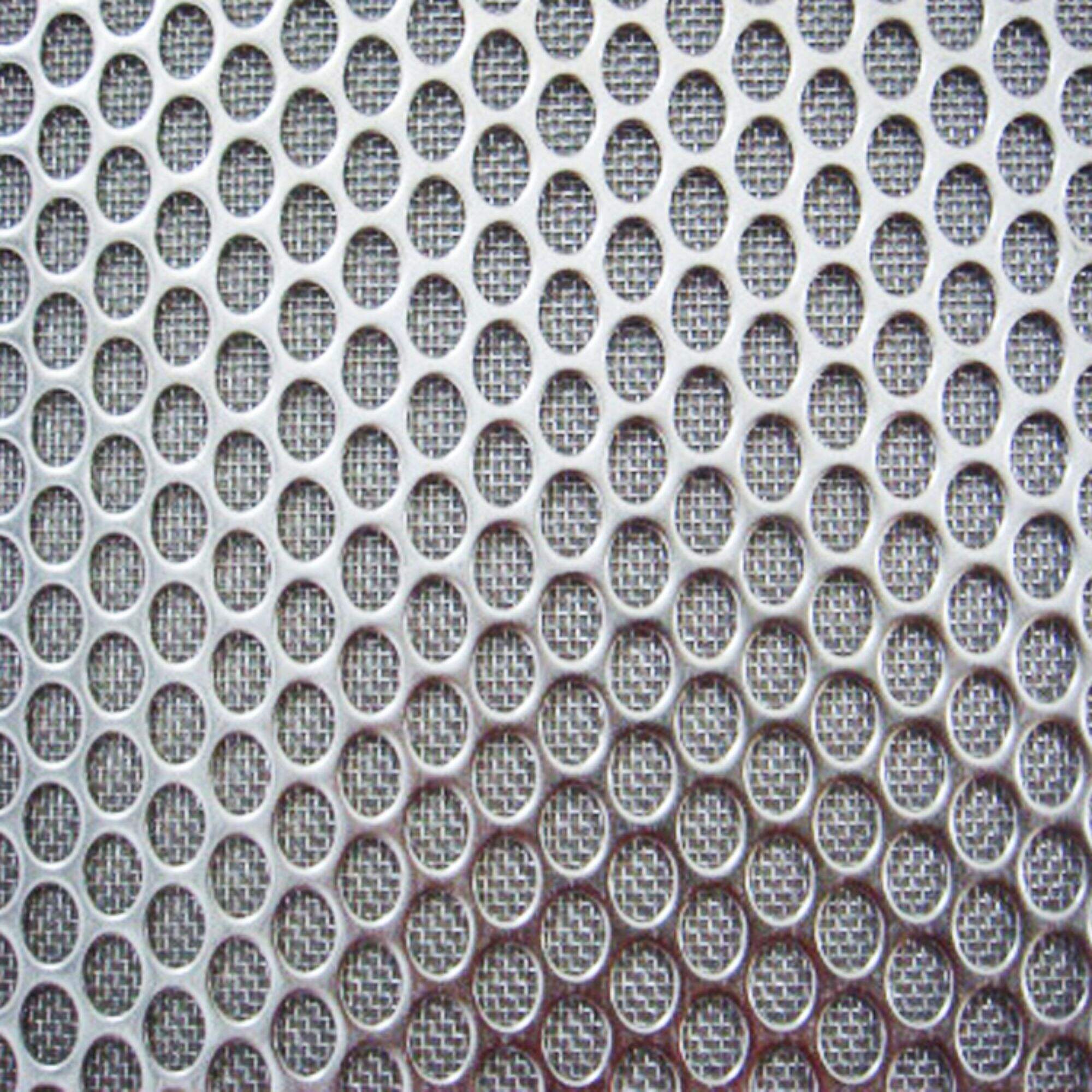

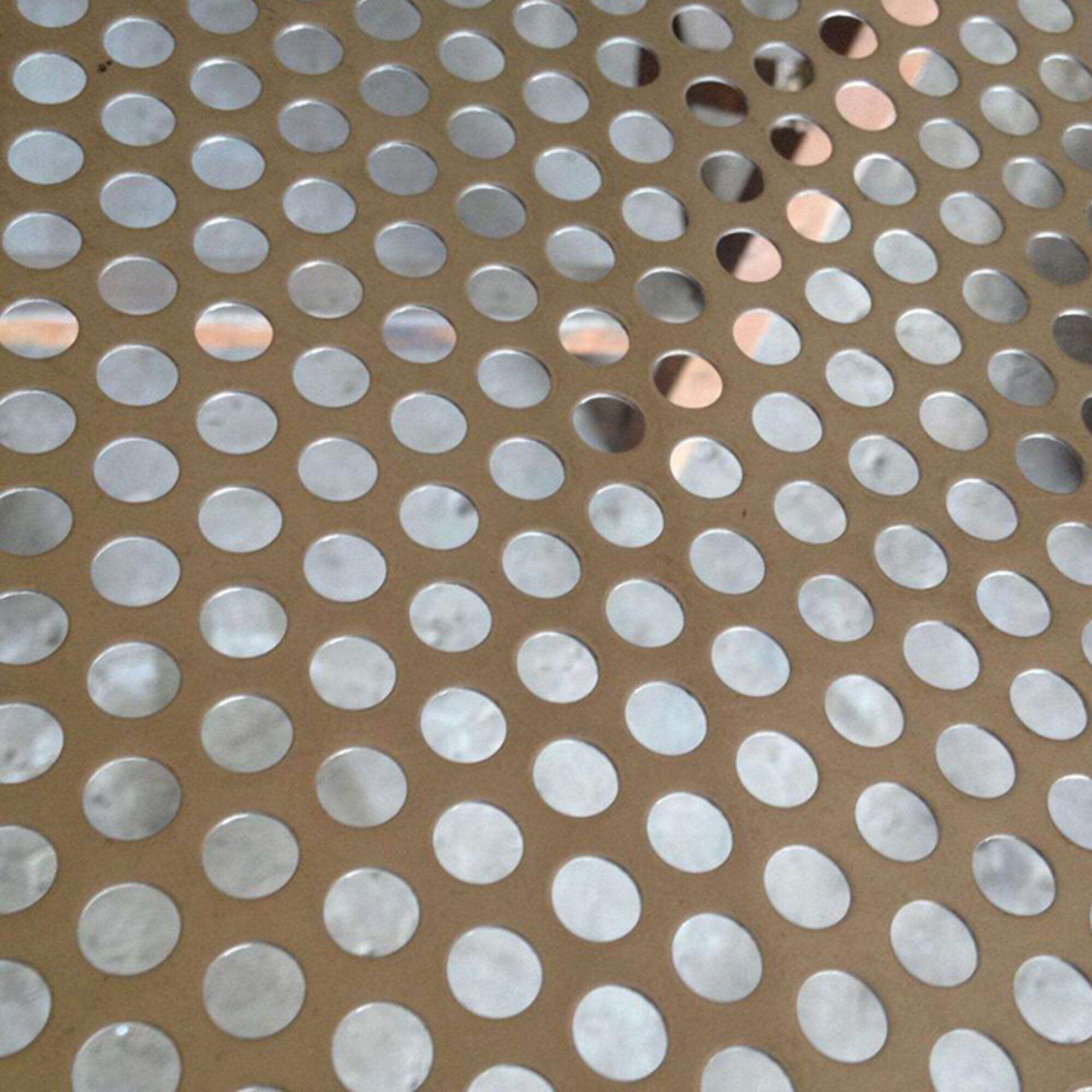

Stainless steel perforated plate

Place of Origin: Wuxi, China

Material: Carbon steel、Stainless steel、Galvanized

Payment Term: T/T, L/C, Western Union, etc

Design Style: customizable

Delivery Time: 7 Days

Transportation: By sea or Land transportation

- Overview

- Parameter

- Inquiry

- Related Products

Stainless steel perforated plate

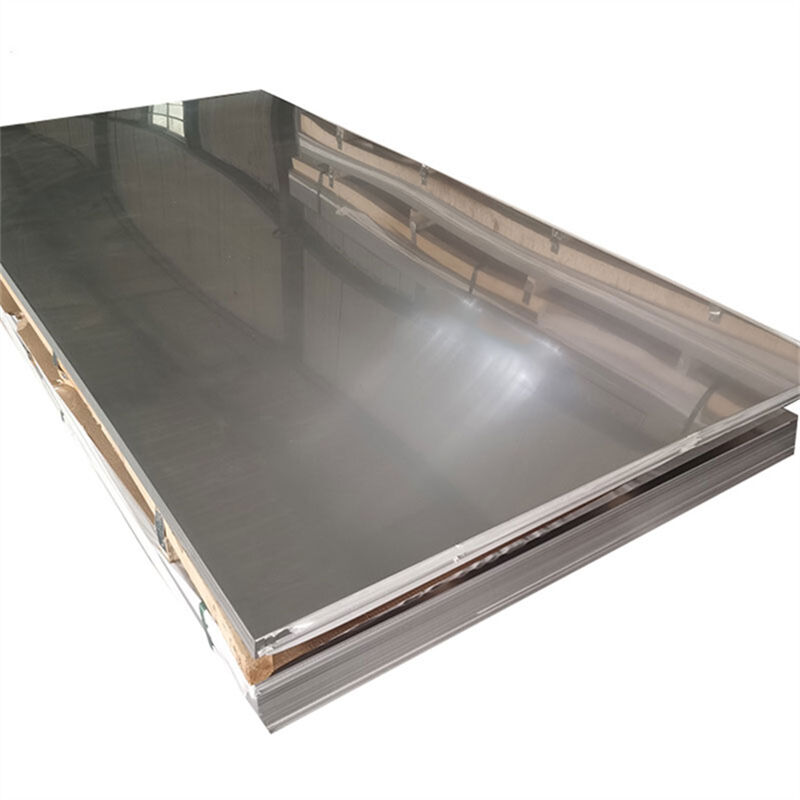

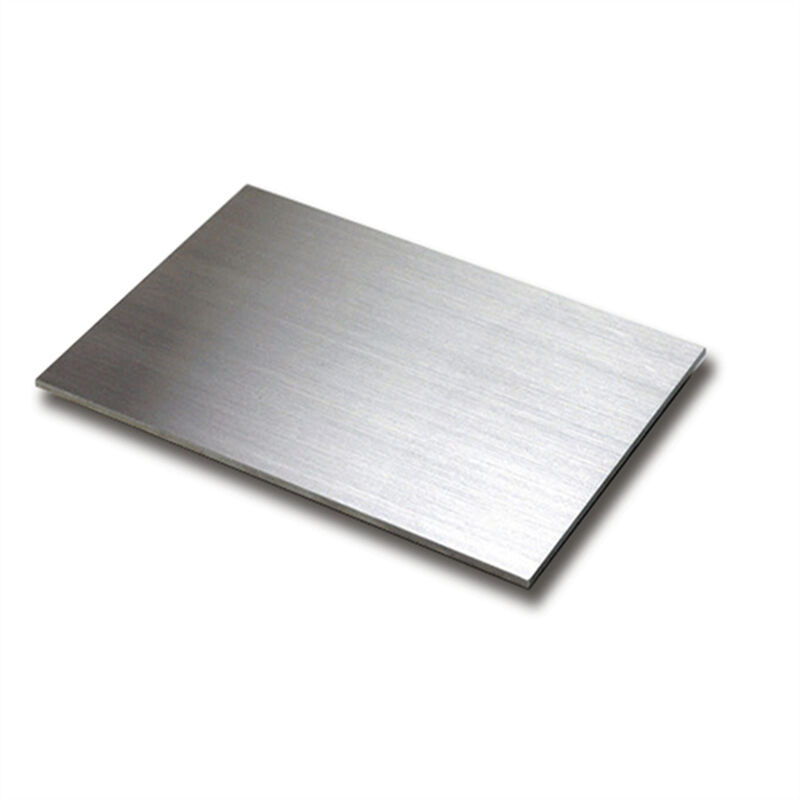

Stainless steel plate has smooth surface, high plasticity, toughness and mechanical strength, and is resistant to corrosion of acid, alkaline gas, solution and other media. It is a kind of alloy steel that is not easy to rust, but it is not absolutely rust free. Stainless steel plate refers to the steel plate resistant to the corrosion of weak media such as atmosphere, steam and water, while acid resistant steel plate refers to the steel plate resistant to the corrosion of chemical etching media such as acid, alkali and salt.

| Specifications of Stainless Steel Sheet/Coil | ||

| Standard | ASTM, JIS, DIN, AISI, KS, EN... | |

| Martensite-Ferritic | Ss 405, 409, 409L, 410, 420, 420J1, 420J2, 420, 430, 431... | |

| Austenite Cr-Ni -Mn | 201, 202... | |

| Austenite Cr-Ni | 304, 304L, 309S, 310S... | |

| Austenite Cr-Ni -Mo | 316, 316L... | |

| Super Austenitic | 904L, 220, 253MA, 254SMO, 654MO | |

| Duplex | S32304, S32550, S31803, S32750 | |

| Austenitic | 1.4372, 1.4373, 1.4310, 1.4305, 1.4301, 1.4306, 1.4318, 1.4335, 1.4833, 1.4835, 1.4845, 1.4841, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4878, 1.4550, 1.4539, 1.4563, 1.4547 | |

| Duplex | 1.4462, 1.4362, 1.4410, 1.4507 | |

| Ferritic | 1.4512, 1.400, 1.4016, 1.4113, 1.4510, 1.4512, 1.4526, 1.4521, 1.4530, 1.4749, 1.4057 | |

| Martensitic | 1.4006, 1.4021, 1.4418, S165M, S135M | |

| Surface Finish | No. 1, No. 4, No. 8, HL, 2B, BA, Mirror... | |

| Specification | Thickness | 3-120mm |

| Width*Length | 1000 x2000, 1219x2438, 1500x3000, 1800x6000, 2000x6000mm | |

| Payment Term | T/T, L/C | |

| Package | Export standard package or as your requirements | |

| Deliver Time | 7-10 working days | |

| MOQ | 1 Ton | |

| Chemical Composition | |||||||

| Grade | C≤ | Si≤ | Mn≤ | P≤ | S≤ | Ni | Cr |

| 201 | 0.15 | 1 | 5.50-7.50 | 0.5 | 0.03 | 3.50-5.50 | 16.00-18.00 |

| 202 | 0.15 | 1 | 7.50-10.00 | 0.5 | 0.03 | 4.00-6.00 | 17.00-19.00 |

| 304 | 0.08 | 1 | 2 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

| 304L | 0.03 | 1 | 2 | 0.045 | 0.03 | 8.00-12.00 | 18.00-20.00 |

| 309 | 0.2 | 1 | 2 | 0.04 | 0.03 | 12.00-15.00 | 22.00-24.00 |

| 309S | 0.08 | 1 | 2 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

| 310 | 0.25 | 1 | 2 | 0.04 | 0.03 | 19.00-22.00 | 24.00-26.00 |

| 310S | 0.08 | 1 | 2 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

| 316 | 0.08 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 316L | 0.03 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 316Ti | 0.08 | 1 | 2 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

| 410 | 0.15 | 1 | 1 | 0.04 | 0.03 | 0.6 | 11.50-13.50 |

| 430 | 0.12 | 0.12 | 1 | 0.04 | 0.03 | 0.6 | 16.00-18.00 |

| Surface Finish of Stainless Steel Sheet/Coil | ||

| Surface Finish | Definition | Application |

| No.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| No.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Electric equipment, Building construction. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| BA/8K Mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

About stainless steel

304 Stainless Steel

304 is a versatile stainless steel that is widely used to make equipment and parts that require good overall performance (corrosion resistance and formability). In order to maintain the inherent corrosion resistance of stainless steel, steel must contain more than 18% chromium and more than 8% nickel.

316 stainless steel

316 stainless steel has excellent corrosion resistance, atmospheric corrosion resistance, and high-temperature strength due to the addition of Mo, which can be used under harsh conditions; excellent work hardening (non-magnetic). Equipment for seawater use,chemical, dye, papermaking, oxalic acid, fertilizer and other production equipment; photographs, food industry, facilities incoastal areas, ropes, CD rods, bolts, nuts.

430 stainless steel

Type 430 Stainless Steel is perhaps the most popular non-hardenable ferritic stainless steel available. Type 430 is known for good corrosion, heat, oxidation resistance, and its decorative nature. It is important to note that when well polished or buffed its corrosion resistance increases. All welding must occur at higher temperatures, but it is easily machined, bent, and formed. Thanks to this combination it is used in a number of different commercial and industrial applications including: Furnace combustion chambers, Automotive trim and molding, Gutters and downspouts, Nitric acid plant equipment, Oil and Gas refinery equipment, Restaurant equipment, Dishwasher linings, Element supports and fasteners.etc.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

GA

GA

IS

IS

AZ

AZ

BN

BN